Hi, we're Action 3D Print, 100% Canadian - “We design. We model. We print. You imagine.”

What can we do for you today?

If delivery by courier is required, please contact us at:

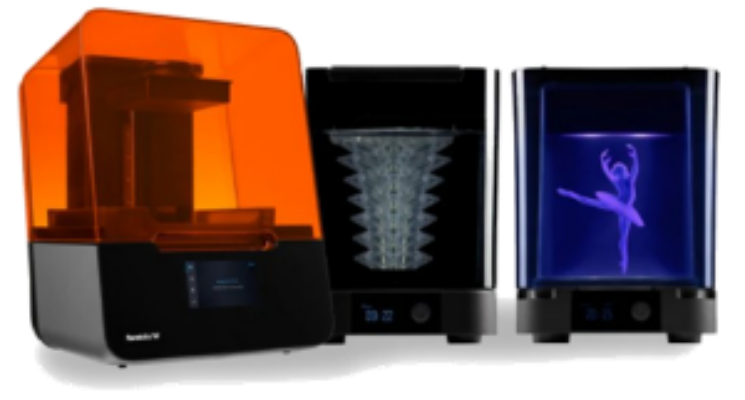

We offer full customized professional 3D designing, modeling and 3D printing to take your idea from concept to production. With our expert 3D designing, modeling, and printing services, we can transform your ideas into tangible products. We are highly skilled dedicated to providing customized solutions from concept to production.

The use of 3D printing techniques allows us to produce high quality parts at a competitive price and technology allows the ability to test multiple models in the same production.

3D design and 3D printing technologies allow:

Design revisions that can be easily and quickly achieved

Revisions to already-designed parts, making them optimal for use, i.e. to resolve fitting issues

Parts to be printed on demand and as needed

Our Brand Promise

We are committed to our clients, big and small, to conduct business with a high degree of craftsmanship, professionalism, integrity, and confidentiality.Utilizing Solidworks, a professional 3D software, and 20 years of experience in the 3D design industry, we provide 3D solutions with added value to fulfill our clients’ vision…all done while providing outstanding personal customer service.We are a local, innovative, professional leading-edge company ready to take your project to reality through 3D design, modeling and printing.

Feel the excitement when you get to hold your idea!